Choosing the right heating tips for efficient induction heating

by Mikael Rosvall on Nov 05, 2025

Overview

Induction heating has emerged as a revolutionary method for heating metals with remarkable efficiency and safety. Unlike traditional heating methods that rely on open flames or direct contact, induction heating uses electromagnetic fields to heat conductive materials quickly and precisely. This contactless technology is especially favored in industrial and automotive applications where precision, speed, and safety are paramount.

The core component that directly interacts with the metal during the induction process is the heating tip. The choice of heating tips significantly impacts the overall heating efficiency, speed, and uniformity of the metal heating process. Selecting the right heating tip for your induction heating application can enhance performance, reduce operational costs, and extend the lifespan of both the induction heater and the tip itself.

Today’s induction heating systems are designed to support various heating tips tailored for different metals and purposes, from releasing seized bolts and axles to pre-heating welded parts before production. These tips not only contribute to more accurate heating but also ensure safer working conditions by eliminating the risks associated with open flames and gas-powered heating tools.

“Choosing the right heating tips is essential for maximizing the benefits of induction heating — including improved heating efficiency, reduced downtime, and enhanced tool maintenance.”

For businesses engaged in car repair or heavy maintenance, efficient metal heating is critical for operational success. The right heating tips, combined with quality induction heaters, provide a safer, faster, and more environmentally friendly solution compared to conventional methods.

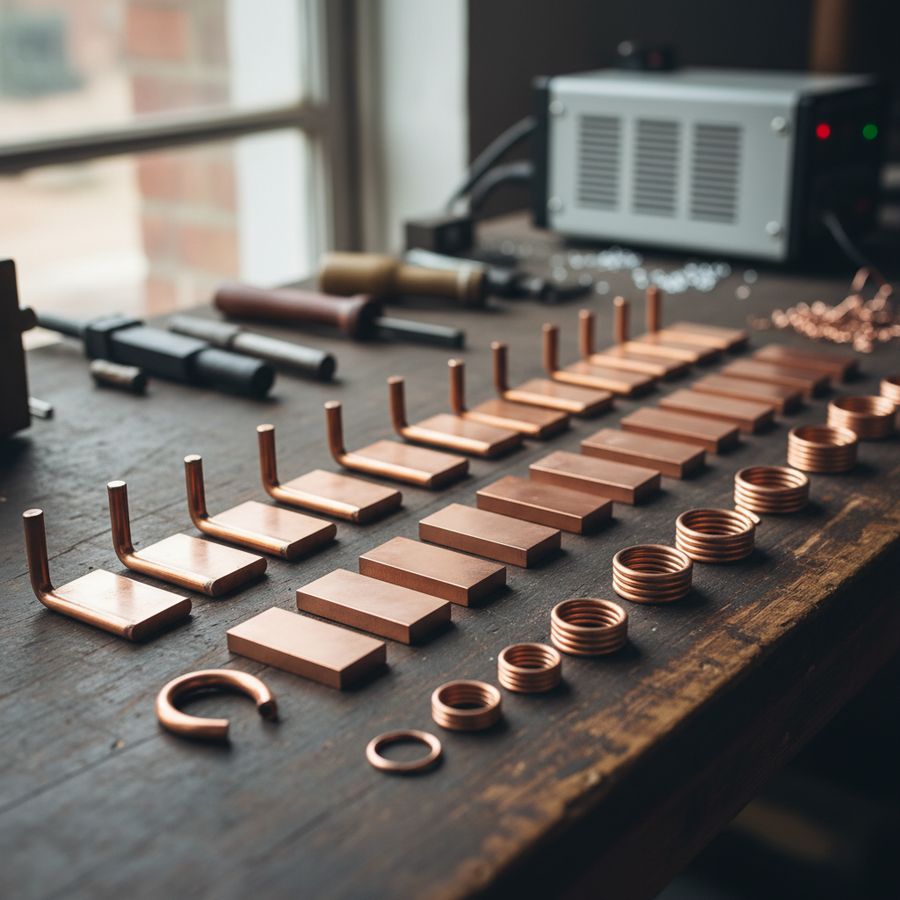

Types of heating tips available

The market offers a range of heating tips designed specifically for induction heating applications, each optimized for different shapes, sizes, and types of metal components. Understanding the types available helps users select the best option for their needs, improving heating efficiency and operational safety.

Common types of heating tips include:

- Standard 90° heating tips: These are versatile and widely used for general-purpose heating. Their angled design allows easy access to bolts, nuts, and joints in tight or awkward spaces.

- Flat heating tips: Ideal for heating larger surface areas uniformly, such as on welded parts or metal plates.

- Circular or coil tips: Designed to surround cylindrical parts or shafts for uniform heating around the circumference.

- Custom-shaped tips: Manufactured for specialized applications requiring precise heat application on complex geometries.

Each heating tip type is engineered to maximize electromagnetic induction efficiency for its target application. For example, the A1200 standard heating tip is popular for its multi-purpose 90° design, offering a balance between accessibility and heating power. Meanwhile, the A500/A800 tips provide replaceable parts for extended use in rugged environments.

Choosing the correct tip type not only improves heating efficiency but also minimizes energy consumption and heat loss, which is essential for reducing operational costs and environmental impact.

“Using the right heating tip tailored for your metal heating task ensures faster heat transfer, less energy waste, and a safer working environment.”

Matching tips to metal types

One of the most critical factors in achieving optimal induction heating efficiency is matching the heating tip to the specific metal type being heated. Different metals have unique electrical and magnetic properties that affect how they respond to electromagnetic induction.

Ferrous metals such as steel and iron typically respond very well to induction heating because of their magnetic permeability. Heating tips designed with coil shapes or angled ends effectively concentrate the electromagnetic field to penetrate deep into these metals, enabling rapid heating. For example, releasing seized bolts or axles on vehicles made of steel is highly efficient with standard 90° tips.

Non-ferrous metals like aluminum, copper, and brass are less magnetic and require specific heating tips designed to optimize eddy current generation for effective heating. Flat or wider coil heating tips can be more suitable for these metals, as they allow heat to be distributed evenly across surfaces that do not respond strongly to magnetic fields.

Besides metal type, other factors such as metal thickness, shape, and surface condition (painted, rusted, or clean) play a role in tip selection. For instance, heavily painted or coated metals may require longer heating times or tips that focus heat to avoid damaging the surface.

Pro tip: Always consult the induction heater manufacturer’s guidelines on heating tip compatibility with metal types to ensure maximum heating efficiency and tool longevity.

“Matching heating tips to metal types is not just about speed but also about preserving the integrity of the metal and the heating tool.”

Maintenance and replacement tips

Proper tool maintenance is indispensable for sustaining the performance and safety of heating tips used in induction heating systems. Regular inspection and maintenance extend the lifespan of heating tips and prevent unexpected downtime in critical operations.

Key maintenance practices include:

- Visual inspection: Check heating tips regularly for signs of wear, cracks, or deformation that could reduce heating efficiency or cause safety hazards.

- Cleaning: Remove any debris, oxidation, or residue from the tip surface to maintain optimal electromagnetic conductivity and heat transfer.

- Proper storage: Store heating tips in a dry, secure place to avoid damage and corrosion.

- Replacement intervals: Follow manufacturer recommendations for replacing heating tips, especially if damage or wear affects heating performance.

Using damaged or worn heating tips can lead to uneven heating, increased energy consumption, and even damage to the induction heater itself. It is also important to use genuine replacement parts designed specifically for your induction heating equipment to ensure compatibility and safety.

Many professional users benefit from keeping a stock of common heating tips like the A500/A800 standard heating tips to quickly replace worn tips and minimize downtime.

“Regular maintenance and timely replacement of heating tips safeguard your investment and ensure consistent heating efficiency.”

Enhancing heating performance

Achieving superior heating efficiency with induction heating involves more than just selecting the right heating tip. Several additional practices can enhance performance and provide consistent, reliable results.

Some effective strategies include:

- Correct positioning: Ensure the heating tip is placed as close as possible to the target metal surface without direct contact. Proper placement maximizes electromagnetic field coupling and heat transfer.

- Optimizing power settings: Adjust the induction heater’s power output based on the metal type and thickness to prevent overheating or insufficient heating.

- Using field enhancers: Field enhancer accessories can concentrate the electromagnetic field in specific areas, reducing heating time and improving precision.

- Pre-heating and post-heating: In welding or assembly processes, controlled pre- and post-heating can improve material properties and reduce stress.

Incorporating these best practices along with choosing the correct heating tip results in faster heating cycles, reduced energy use, and safer operations. Moreover, induction heating’s clean and contactless nature reduces the risk of accidents and lowers insurance costs for businesses.

“Fine-tuning your induction heating setup with the right tips and techniques unlocks the full potential of this efficient metal heating technology.”

Conclusion

Choosing the right heating tips for induction heating is a vital step in optimizing metal heating applications, particularly in demanding environments like automotive repair and heavy maintenance. From understanding the different types of heating tips available to matching them with specific metal types, each decision impacts heating efficiency, safety, and tool longevity.

Regular maintenance and timely replacement of heating tips ensure that your induction heating equipment continues to perform reliably, minimizing downtime and operational costs. Additionally, employing best practices such as proper positioning, power optimization, and the use of field enhancers can significantly boost heating performance.

As industries continue to move toward safer, cleaner, and more environmentally friendly heating solutions, induction heating with the correct heating tips stands out as a smart investment. It enables faster, more precise metal heating without the hazards of open flames or gas, supporting greener and more productive workplaces.

“Investing in the right heating tips and maintaining them diligently is key to unlocking efficient, safe, and cost-effective induction heating solutions.”