Maintenance and care tips for long-lasting induction heaters

bis Mikael Rosvall auf Nov 05, 2025

Overview

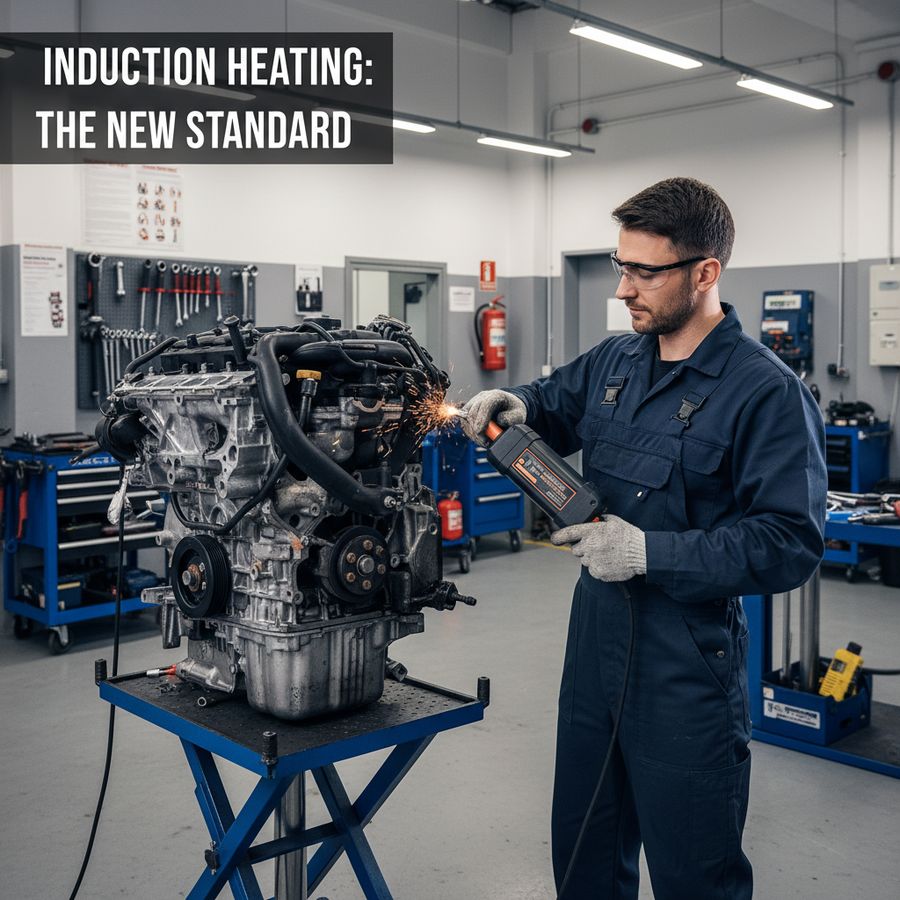

Induction heater maintenance is essential to ensure the longevity and optimal performance of these advanced heating tools. Induction heaters, widely used in automotive repair and industrial applications, provide a safer, more efficient alternative to traditional open flame heating methods. Their contactless nature allows for precise heating of metal components like bolts, axles, and welded parts, significantly reducing risks and operational downtime.

Given that induction heaters operate in demanding environments, they must be kept in excellent condition to maintain their functionality. Long-lasting equipment relies not only on the quality of the device itself but also on consistent care and upkeep. Understanding the basics of your induction heater’s operation, components, and typical usage scenarios forms the foundation for effective maintenance practices.

Modern induction heaters, such as portable models and those equipped with integrated cooling systems, are designed to withstand tough conditions. However, wear and tear are inevitable without proper attention to routine maintenance and cleaning. The benefits of proactive maintenance include improved safety, reduced repair costs, and extended service life, making it a critical part of your operational workflow.

“A well-maintained induction heater not only performs better but also contributes to a safer and more productive workspace by minimizing unexpected breakdowns.”

In this guide, we will explore practical steps for routine care, strategies to prevent common wear issues, cleaning and storage best practices, and tips on when to replace spare parts. These insights will help you maximize your equipment’s lifespan and maintain its high-efficiency heating capabilities.

Routine maintenance procedures

Implementing a comprehensive induction heater maintenance routine is key to ensuring your device remains reliable over time. Routine maintenance involves a series of checks and actions performed regularly to detect early signs of wear or malfunction. These procedures should be integrated into your daily or weekly workflow depending on the frequency of use.

Start by inspecting the heater’s external components such as cables, connectors, and the heating coil for visible damage or corrosion. Pay close attention to the cooling system, as overheating is a common cause of equipment failure. Ensure that cooling fans and vents are unobstructed and functioning correctly to prevent heat buildup.

Electrical connections should be tightened and checked for any loose wiring, which can cause intermittent power loss or sparks. Testing the unit’s output power and temperature regulation with a calibrated meter can help detect performance inconsistencies early. Any unusual noises, vibrations, or smells during operation should be addressed immediately to avoid further damage.

Documenting maintenance activities is also beneficial. Keeping a log helps track recurring issues and identify parts that may need replacement soon. It also assists technicians in diagnosing problems faster and ensures compliance with safety regulations.

-

Regularly inspect cables and connectors for wear and tear

-

Check and clean cooling vents and fans to avoid overheating

-

Test output power and temperature accuracy routinely

-

Tighten electrical connections and look for corrosion

-

Keep a detailed maintenance log for reference

By adhering to these routine maintenance procedures, you can reduce downtime, enhance safety, and promote the longevity of your induction heater, ultimately contributing to more efficient and cost-effective operations.

Preventing common wear issues

Preventing wear and tear on your induction heater is a proactive approach that preserves its performance and extends its service life. Common wear issues often stem from improper handling, environmental factors, or inadequate maintenance practices. Understanding these causes will help you implement effective prevention strategies.

One of the most frequent problems is damage to the heating tips and coils due to excessive heat or mechanical impact. Using the heater within recommended parameters and avoiding prolonged continuous operation without cooling breaks can mitigate this risk. Additionally, always handle the unit carefully to prevent physical damage to sensitive components.

Environmental exposure to dust, moisture, and chemicals can accelerate corrosion and electrical failures. Storing the heater in a clean, dry environment and using protective covers during downtime can significantly reduce such risks. Furthermore, avoid exposing cables to sharp edges or heavy objects to prevent insulation damage.

Operator training also plays a vital role in preventing wear. Ensuring that technicians understand proper usage guidelines, including correct positioning of heating tips and safe operating temperatures, reduces the likelihood of misuse and premature wear.

-

Operate within manufacturer-recommended temperature and duration limits

-

Protect equipment from dust, moisture, and corrosive substances

-

Store in a dry, clean area with protective covers when not in use

-

Avoid mechanical shocks and rough handling

-

Train operators thoroughly in safe and proper use

“Preventing common wear issues is not just about safeguarding the heater but also about maintaining workplace safety and ensuring consistent heating performance.”

By implementing these preventive measures, you can minimize costly repairs and maintain the efficiency and reliability of your induction heater over years of operation.

Cleaning and storage guidelines

Proper cleaning and storage are fundamental to effective induction heater maintenance. Regular cleaning removes contaminants that can impair performance and lead to overheating or electrical faults. Meanwhile, appropriate storage practices protect your equipment from environmental damage during periods of inactivity.

For cleaning, always disconnect the heater from the power source before beginning any procedure. Use a soft, dry cloth to wipe external surfaces, removing dust, grease, and dirt. Avoid using harsh chemicals or abrasive materials that may damage the device’s casing or components. For stubborn residues on heating tips or coils, a mild detergent dampened cloth can be used, followed by thorough drying.

Check cooling vents and fans regularly and clear any accumulated debris using compressed air or a soft brush. This ensures proper airflow and prevents overheating. Never immerse any part of the induction heater in water or liquids.

When storing your induction heater, choose a clean, dry location away from direct sunlight or heat sources. Ideally, use the original packaging or a protective case designed for the heater to prevent dust accumulation and mechanical damage. Coil cables loosely without kinks and avoid placing heavy objects on top of the equipment.

-

Disconnect power before cleaning to ensure safety

-

Use soft, dry cloths or mild detergents for cleaning

-

Clean cooling vents with compressed air or soft brush

-

Store in a dry, temperature-controlled environment

-

Protect with original packaging or dedicated cases

-

Handle cables carefully to avoid damage

Following these cleaning and storage guidelines will safeguard your induction heater’s components, reduce the risk of malfunction, and help maintain optimal heating performance for years to come.

Extending heater lifespan

Extending the lifespan of your induction heater requires a holistic approach combining routine maintenance, preventive care, and smart operational habits. Investing time in these practices yields significant returns through reduced repair costs and improved productivity.

Begin by adhering strictly to manufacturer instructions regarding operating conditions, including duty cycles and recommended temperatures. Avoid overusing the heater without allowing adequate cooling periods, as excessive heat stress shortens component life. Incorporating the use of cooling accessories can also help maintain safe operating temperatures.

Regularly replacing worn parts with genuine spare parts ensures your heater maintains its designed efficiency and safety standards. Using non-genuine or incompatible parts can lead to suboptimal performance and damage.

Incorporate scheduled inspections to catch early signs of wear, corrosion, or electrical faults. Early detection allows for timely intervention, preventing more severe damage. Prioritize training for all users to maintain consistent and safe operation practices, minimizing operator errors that can accelerate wear.

-

Follow manufacturer guidelines for operation and duty cycles

-

Allow adequate cooling times between heating sessions

-

Use genuine spare parts for replacements and repairs

-

Perform scheduled inspections to detect issues early

-

Train operators thoroughly on proper use and safety

“A well-cared-for induction heater not only lasts longer but also delivers reliable performance, ensuring safer and more efficient operations.”

By implementing these lifespan extension strategies, you safeguard your investment and maintain a safer, greener, and more productive work environment.

When to replace parts

Knowing when to replace components is crucial for maintaining the safety and performance of your induction heater. Even with diligent induction heater maintenance, parts will inevitably wear out over time due to heat cycles, mechanical stress, and environmental exposure.

Common parts that require periodic replacement include heating tips, coils, cables, and cooling fans. Signs that indicate replacement is necessary include visible wear, cracks, discoloration, reduced heating efficiency, unusual noises, or intermittent electrical issues. Ignoring these symptoms can lead to equipment failure or safety hazards.

Always source genuine spare parts designed specifically for your heater model to ensure compatibility and maintain warranty coverage. Replacing parts promptly helps avoid more extensive damage and downtime. Document the date and details of each replacement to maintain an accurate maintenance history.

-

Replace heating tips and coils at first signs of wear or damage

-

Inspect and replace cables if insulation is cracked or frayed

-

Change cooling fans if airflow is diminished or noisy

-

Use genuine spare parts for all replacements

-

Keep records of part replacements for maintenance tracking

Timely replacement of worn parts is a vital component of your overall maintenance strategy, ensuring that your induction heater remains safe, reliable, and efficient throughout its operational lifespan.

Conclusion

Maintaining your induction heater with consistent and informed care is crucial for achieving long-lasting equipment performance. Routine inspections, cleaning, preventive measures, and timely spare parts replacement all play a role in extending the heater’s lifespan and enhancing workplace safety.

By incorporating these cleaning tips and maintenance procedures into your workflow, you can minimize costly downtime and maximize your investment's return. The advanced technology of the induction heater provides a cleaner, safer, and more efficient heating solution, but it requires proper maintenance to do so.

“Proactive maintenance and care not only protect your induction heater but also empower your team to work smarter, safer, and more productively.”

Embrace these maintenance strategies to ensure your induction heater continues to deliver reliable, high-performance heating for years to come. For more insights and resources, visit Induktion Store.