Overview

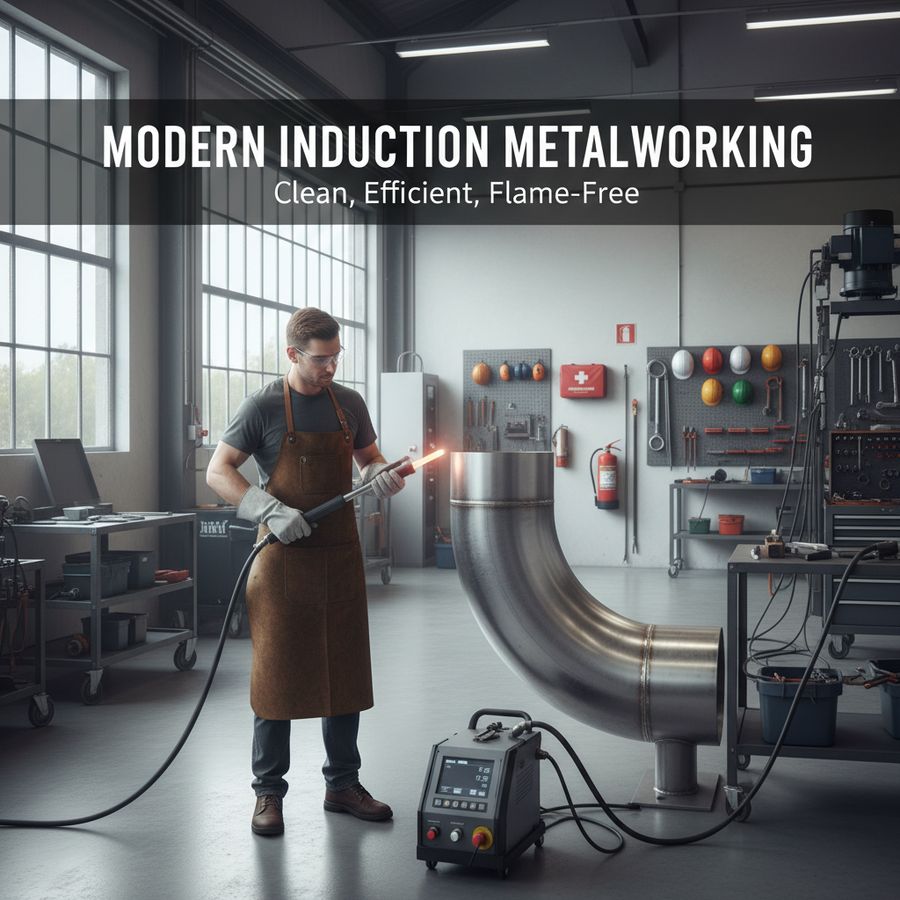

Choosing the right induction heater for metalwork is a critical decision for professionals and hobbyists alike who require efficient, safe, and clean heating solutions. Induction heating is a contactless method that uses electromagnetic fields to heat metal parts quickly and precisely without an open flame. This technology has revolutionized metalwork heating by offering a safer alternative to traditional methods, such as torches or ovens, which can be hazardous and less energy-efficient.

Induction heaters are widely applied in automotive repair, manufacturing, welding, and heavy maintenance operations. Their ability to release mechanical joints, heat alignments, and pre-/post-heat welded parts makes them indispensable for speeding up workflows while reducing risks. Moreover, induction heaters contribute to a cleaner working environment by eliminating gas emissions and open flames, which enhances workplace safety and lowers insurance costs.

Induction heater selection hinges on factors like power output, portability, compatibility with various metals, and available heating accessories. Portable heaters have become particularly popular due to their flexibility and ease of use on-site or in workshops. As industries seek greener alternatives, induction heating has grown in demand as a carbon-neutral, environmentally friendly solution.

“Induction heating is not only about efficiency but also about creating a safer, cleaner workspace that supports sustainable practices.”

In this guide, we will explore key features to consider, the significance of power and portability, compatibility considerations for different metals, essential heating tips and accessories, and budget factors to help you make an informed choice when investing in an induction heater for metalwork.

Key features to consider

When selecting an induction heater for metalwork heating, understanding the core features that impact performance and usability is essential. The right induction heater should combine durability, power, and versatility to meet the demands of your specific applications.

Power output is arguably the most important feature. It determines how quickly and effectively the heater can raise the temperature of metal parts. Higher wattage units, such as 12 kW models, are ideal for heavy-duty tasks like releasing seized bolts or heating large welded components. On the other hand, smaller power output units suffice for lighter or more precise heating jobs.

Portability and weight are crucial for users who need to move the heater between job sites or around a large workspace. Models weighing around 19 kg, such as the ALESCO ACE12, offer a good balance of powerful heating and manageable transportability. Compact designs with integrated cooling systems extend operational time without overheating, increasing productivity.

Heating tips and accessories enhance the versatility of your induction heater. Different tips are designed for various applications — from standard 90° tips for general heating to specialized tips for confined spaces or specific metal shapes. Accessories like field enhancers improve heating efficiency and precision, ensuring you get the best results with minimal energy waste.

Durability and build quality should not be overlooked. Induction heaters used in metalwork environments face tough conditions, so selecting equipment made with robust components and long-lasting materials is vital. This guarantees reliable performance and reduces maintenance costs over time.

“A high-quality induction heater with the right features is an investment that pays off through faster jobs, safer processes, and lower operational costs.”

Ultimately, the induction heater selection process should consider how these features align with your metalwork tasks, ensuring you choose a tool that improves efficiency and workplace safety.

Power and portability

Power output and portability are two interlinked factors that significantly influence the effectiveness and convenience of an induction heater for metalwork heating. Selecting a unit with the right power rating ensures you can handle the scale and type of heating jobs required, while portability affects how easily you can transport and maneuver the heater.

Power output is measured in kilowatts (kW), and it directly impacts heating speed and depth. For demanding tasks such as loosening large, rusted bolts or pre-heating thick welds, a heater with a power output of 12 kW or higher is recommended. These models can deliver rapid, uniform heating, reducing downtime and manual labor.

Conversely, for smaller-scale or precision jobs, a lower power portable heater can be more appropriate. These units consume less power, are lighter, and are often easier to control, making them ideal for frequent use on lighter mechanical parts or in tight spaces.

Portability is essential for users who need flexibility. Portable induction heaters, like the ALESCO A80V or A80 models, are designed to be lightweight and compact without sacrificing power output. This balance allows technicians to move freely around workshops, garages, or even outdoor sites, improving workflow efficiency.

Integrated cooling systems in portable units prevent overheating during continuous use, enhancing operational safety and heater lifespan. Additionally, cords and hose lengths—such as the 1.7-meter cable on some models—affect how freely you can operate the device in confined or complex environments.

-

Choose a power output aligned with your heating needs: higher for heavy-duty, lower for lighter tasks.

-

Consider the weight and size for ease of transport and use on-site.

-

Look for built-in cooling and ergonomic designs to support extended work periods.

“A portable heater with adequate power output transforms metalwork heating by boosting efficiency without compromising safety or mobility.”

By carefully weighing power and portability, you ensure the induction heater you select will support both your current and future metalwork heating needs.

Compatibility with metals

Understanding metal compatibility is fundamental when choosing an induction heater for metalwork heating. Induction heating relies on electromagnetic fields to induce heat directly within conductive metals, but not all metals respond the same way or with equal efficiency.

Ferrous metals such as steel and iron heat up quickly under induction due to their magnetic properties. These metals are ideal candidates for induction heaters, making them perfect for automotive repair, welding preparation, and heavy maintenance.

Non-ferrous metals like aluminum, copper, and brass are less responsive because they are non-magnetic. However, with the right induction heater and heating tips, these metals can still be heated effectively. It is essential to select a heater that offers adjustable power output and specialized accessories to accommodate such metals without damaging them.

Thickness and shape of the metal also affect heating efficiency. Thicker materials require more power and longer heating times, while complex shapes might need customized heating tips or field enhancers to ensure uniform temperature distribution.

Many modern induction heaters offer versatile heating tips designed to work on any metal type, enhancing the flexibility of your equipment. For example, the ALESCO A80V induction heater is praised for its ability to work effectively on virtually any metal, providing users with a reliable all-around solution.

“Ensuring your induction heater matches the metal type and geometry is key to achieving efficient, safe, and damage-free heating.”

Before purchasing, consider the metals you frequently work with, and prioritize models with adjustable settings and compatible accessories. This approach maximizes the utility and lifespan of your induction heater while broadening its application range.

Heating tips and accessories

Heating tips and accessories play a pivotal role in enhancing the functionality and precision of your induction heater for metalwork applications. Selecting the right tips and complementary tools can significantly improve heating efficiency, safety, and ease of use.

Heating tips come in various shapes and sizes tailored for specific tasks. The standard 90° heating tip is versatile for general metal heating, while specialized tips are designed for confined spaces, tubular parts, or surface heating. Choosing the appropriate tip ensures uniform heat distribution and reduces the risk of overheating or damaging sensitive components.

Field enhancers are an important accessory that boosts the magnetic field concentration in targeted areas. This results in faster heating times and more focused heat application, which is ideal for releasing stubborn mechanical joints or heating welded parts with minimal energy waste.

Other accessories such as replacement kits, hose packages, and integrated cooling units contribute to the longevity and performance of the induction heater. They minimize downtime caused by wear and tear and allow for seamless maintenance.

-

Standard and specialized heating tips for diverse metal shapes and configurations.

-

Field enhancers to concentrate heat and improve efficiency.

-

Replacement kits and hose packages for easy maintenance and sustained performance.

-

Integrated coolers to prevent overheating during extended operations.

“The right combination of heating tips and accessories transforms an induction heater into a versatile, efficient, and user-friendly metalwork tool.”

When selecting your induction heater, ensure the availability of compatible accessories to maximize the benefits of your investment and tailor the heating process to your specific metalwork requirements.

Budget considerations

Budget is a crucial factor when selecting the right induction heater for metalwork heating. While it is tempting to choose the lowest-priced option, investing in a quality heater with appropriate power output, durability, and accessories will yield better long-term value.

Basic portable induction heaters with moderate power output and standard features are available at entry-level prices, making them suitable for light to medium-duty tasks. However, these units may lack the advanced cooling systems, versatile heating tips, or robust build quality needed for heavy or continuous use.

High-end models, such as 12 kW heaters with integrated cooling systems and a broad range of accessories, come at a higher upfront cost but offer superior performance, safety, and efficiency. Their durability reduces maintenance expenses and downtime, which can be costly in professional settings.

Consider the total cost of ownership, including:

-

Initial purchase price

-

Availability and cost of heating tips and replacement parts

-

Energy consumption and operational efficiency

-

Maintenance and repair expenses

Financing options or phased purchases of heaters and accessories can help spread costs, especially for businesses upgrading their equipment. Prioritize models with strong manufacturer support and warranties to safeguard your investment.

“A well-chosen induction heater balances initial cost with operational savings, safety improvements, and long-term reliability.”

By aligning your budget with your practical needs and the quality features discussed, you can select an induction heater that delivers maximum value and contributes to safer, faster metalwork heating.

Conclusion

Choosing the right induction heater for metalwork heating involves careful consideration of multiple factors: power output, portability, metal compatibility, heating tips and accessories, and budget. Each element plays a vital role in ensuring that your induction heater meets your specific needs efficiently and safely.

Induction heating is a modern, eco-friendly alternative to traditional heating methods. By choosing a high-quality, durable induction heater that includes the right features and support, you can boost workflow productivity, minimize operational risks, and improve workplace safety. To explore your options, visit Induktion Store.

Investing in a versatile induction heater with a balanced power output and portable design enables you to tackle a wide range of metalwork heating tasks—from releasing seized mechanical joints to pre-heating welded parts. Complementing your heater with suitable heating tips and accessories further optimizes performance and precision.

Finally, align your choice with your budget but consider the total cost of ownership and long-term benefits. A reliable induction heater is not just a tool but a valuable asset that elevates your metalwork processes while supporting a greener, safer future.

“The right induction heater is an investment in efficiency, safety, and sustainability that transforms metalwork heating for the better.”