Essential heating tips for efficient metal joint release Essential heating tips for efficient metal joint release

by Mikael Rosvall on Nov 29, 2025

Overview

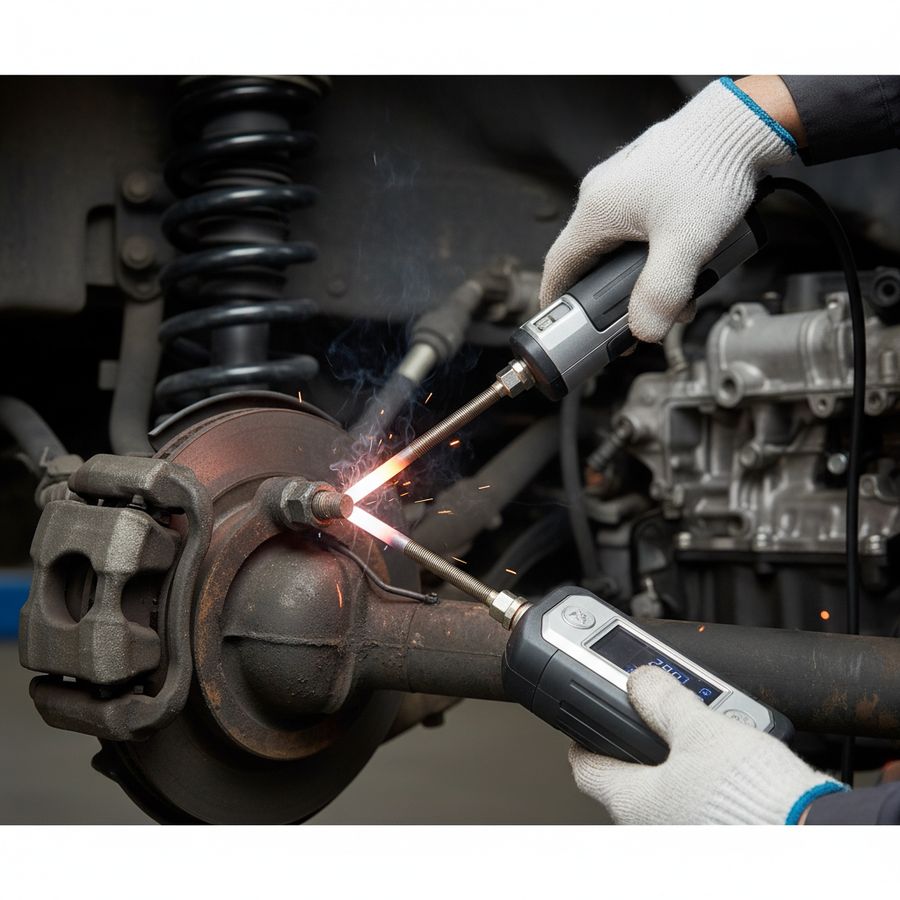

Efficient metal joint release is a critical operation in automotive repair, heavy machinery maintenance, and various industrial applications. Traditional methods often involve open flames or manual force, which can be hazardous, time-consuming, and damaging to components. Today, induction heating has emerged as a revolutionary technique, offering a safer, cleaner, and more precise way to loosen stubborn metal joints.

Induction heating uses electromagnetic fields to heat metal parts without direct contact or open flames, resulting in rapid and uniform heating. This method significantly reduces the risk of damage to surrounding materials, lowers CO₂ emissions, and enhances overall workplace safety. For technicians and repair professionals, mastering efficient heating techniques is essential to optimize workflow and protect valuable components.

By understanding the principles of metal expansion, appropriate use of induction heaters, and maintaining strict temperature control, operators can maximize the effectiveness of metal joint release processes. This blog post will guide you through essential heating tips, focusing on best practices to ensure successful outcomes while prioritizing induction heating safety.

“Switching to induction heating not only improves efficiency but also drastically reduces workplace hazards associated with traditional heating methods.”

Whether you are dealing with seized bolts, axles, or other mechanical joints, adopting these expert tips will empower you to work smarter and safer, ultimately saving valuable time and reducing operational costs.

Understanding metal joint expansion

Metal joint release hinges on the fundamental principle of thermal expansion. When metals are heated, their molecules vibrate and move apart, causing the material to expand. This expansion can help loosen tight or corroded joints such as bolts, nuts, or pressed fittings, making disassembly easier.

Different metals expand at different rates, depending on their thermal expansion coefficients. For example, steel expands less than aluminium under the same heating conditions. Understanding these variations is crucial to applying the right amount of heat without causing damage.

In applications like automotive repair heating, precision is key. Overheating can cause warping or alter the metallurgical properties of components, while underheating might not provide enough expansion to break the bond. Additionally, uneven heating can lead to stress points that may crack or deform the metal.

When using induction heating for metal joint release, the heat is generated internally within the metal, leading to rapid and localized expansion. This contactless method ensures that only the targeted area is heated, preserving surrounding parts and coatings.

“Effective metal joint release depends on controlled expansion — heating just enough to loosen the joint without compromising the integrity of the metal.”

Properly managing the heating process by understanding metal behaviour under heat is the foundation for successful and efficient metal joint release.

Using induction heaters effectively

Induction heaters are designed to deliver focused, rapid heating to metal components, making them ideal for releasing joints in automotive and industrial repair. To use an induction heater effectively, it is essential to select the right tool and accessories for the specific application.

First, choose a heater with sufficient power output (measured in kilowatts) to reach the required temperature quickly. Portable induction heaters like the ALESCO ACE12 or A80V models offer versatility and ease of handling, allowing technicians to work efficiently in tight spaces.

Equipping the heater with the correct heating tip is equally important. Standard heating tips with a 90° design are multipurpose and suitable for most joints, while specialized tips can target hard-to-reach areas or provide more precise heating patterns.

To maximize efficiency:

-

Position the induction coil or heating tip as close to the joint as possible without contact to ensure optimal electromagnetic coupling.

-

Use steady, controlled heating rather than rapid bursts to avoid thermal shock or uneven expansion.

-

Monitor the heating duration carefully; prolonged exposure can overheat the joint and surrounding materials.

-

Utilize integrated cooling features, if available, to prevent overheating the induction heater itself and enable longer work cycles.

Automation and digital controls on advanced induction heaters can assist in maintaining consistent heating parameters, further improving results and safety.

“Using induction heaters with the right accessories and technique delivers fast, clean, and efficient metal joint release without the hazards of open flames.”

Temperature control tips

Maintaining precise temperature control during induction heating is vital for efficient metal joint release and component preservation. Unlike open flame methods, induction heating offers superior control, but operators must still adhere to best practices to avoid mistakes.

Start by understanding the target temperature range for the metal and joint type. For most steel components, heating between 150°C to 300°C (302°F to 572°F) is sufficient to achieve expansion without risking metallurgical damage. Exceeding these limits can cause metal fatigue, warping, or loss of mechanical properties.

Temperature monitoring tools such as infrared thermometers or thermal cameras allow real-time feedback during heating. Use these devices frequently to ensure temperature remains within the safe range.

Additional tips for temperature control include:

-

Gradually ramp up heat to prevent sudden temperature spikes.

-

Allow cooling intervals if multiple heating cycles are required.

-

Be aware of paint, coatings, or nearby sensitive components that may have lower heat tolerances.

-

Use the induction heater’s adjustable power settings to fine-tune output.

“Consistent temperature control not only improves joint release success but also extends the life of both tools and components.”

With the right approach, temperature control becomes a powerful tool in the technician’s arsenal for safe, effective, and efficient heating operations.

Avoiding damage during heating

While induction heating is inherently safer than traditional methods, improper use can still lead to damage of metal components or adjacent parts. Avoiding such damage requires careful planning, technique, and awareness of the heating environment.

Key risks include:

-

Overheating: Excessive heat can alter metal microstructure, warp parts, or degrade coatings.

-

Uneven heating: May cause thermal stresses leading to cracks or fractures.

-

Damage to non-metallic parts: Rubber seals, plastic components, or paint can be destroyed if exposed to high temperatures.

To mitigate these risks, always position the induction coil accurately and focus heating strictly on the metal joint. Shield or remove sensitive components when possible. Employ gradual heating and monitor temperatures closely.

Additionally, using induction heaters with integrated cooling systems helps maintain stable operating temperatures and prevents overheating of the heating device, reducing the risk of accidental damage during extended use.

“Precision and patience during induction heating protect valuable components and ensure long-term equipment reliability.”

Following these precautions will help you leverage induction heating’s benefits without compromising the integrity of your workpieces or tools.

Safety best practices

Safety is paramount when using induction heating equipment, especially in automotive repair and industrial metal joint release scenarios. Despite induction heating being cleaner and safer than open flames, several best practices must be observed to protect operators and the workspace.

Firstly, always wear appropriate personal protective equipment (PPE), including heat-resistant gloves, safety glasses, and protective clothing. Induction heaters generate strong electromagnetic fields and high temperatures, so minimizing skin exposure is critical.

Ensure the workspace is well-ventilated and free from flammable materials or vapors. Unlike gas torches, induction heaters do not produce open flames, but indirect heat can still ignite combustible substances.

Additional safety tips include:

-

Follow manufacturer guidelines for equipment setup, operation, and maintenance.

-

Regularly inspect cables, coils, and connectors for wear or damage.

-

Use the heater’s built-in safety features, such as automatic shutoff and temperature limiters.

-

Train all operators thoroughly on induction heating safety protocols and emergency procedures.

“Proper training and adherence to safety protocols transform induction heating into a highly reliable and secure metal joint release method.”

By fostering a culture of safety, technicians can confidently utilize induction heating to enhance productivity while minimizing risks.

Conclusion

Efficient metal joint release using induction heating is a game-changer for automotive repair and industrial maintenance. By understanding metal expansion principles, selecting and using induction heaters correctly, maintaining precise temperature control, and adhering to safety best practices, technicians can achieve faster, safer, and more reliable outcomes.

Induction heating tips shared in this guide equip professionals with the knowledge to optimize their workflows, reduce downtime, and protect valuable equipment. Transitioning away from traditional open flames to induction heating not only enhances repair quality but also fosters a cleaner, greener, and safer work environment. For more insights, check out Induktion Store.

Embracing these efficient heating techniques will empower your team to tackle challenging metal joint releases with confidence and precision, ultimately saving time and lowering operational costs.

“Induction heating is not just a tool — it’s an investment in safer, faster, and more sustainable metal joint release processes.”

Start integrating these essential heating tips today to revolutionize your repair and maintenance operations.