How induction heating enhances metal alignment and welding

by Mikael Rosvall on Nov 22, 2025

Overview

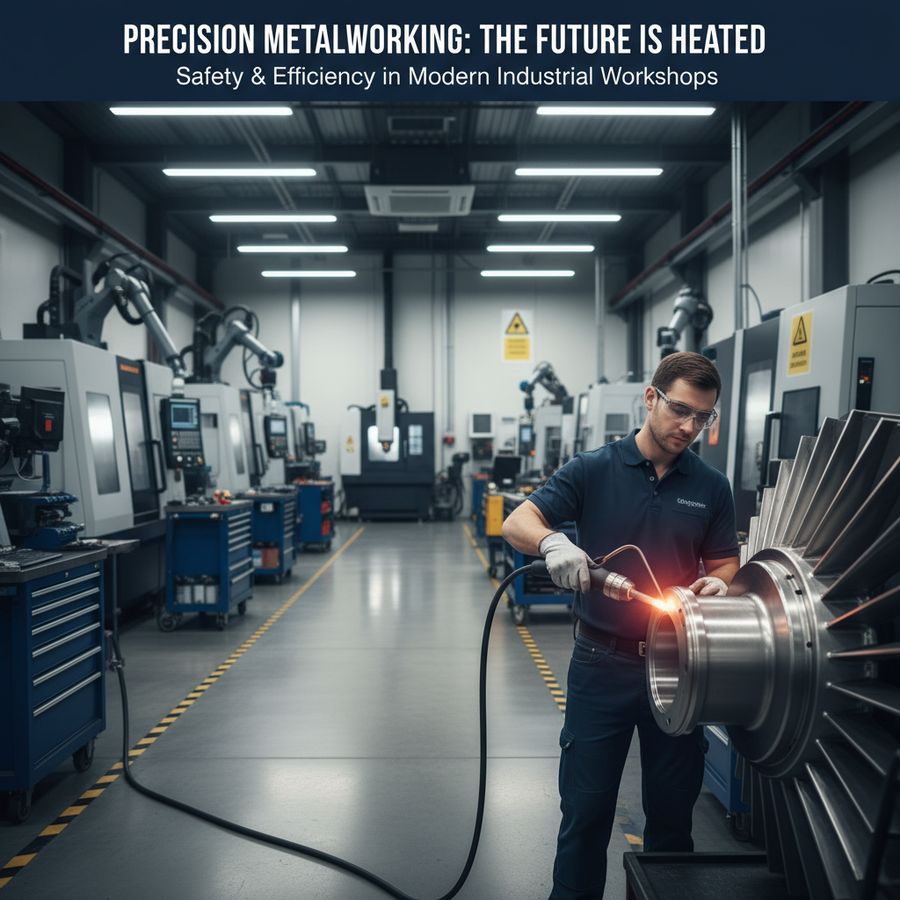

Induction heating has revolutionized the way metal alignment and welding processes are approached in modern manufacturing and repair industries. Unlike traditional heating methods that rely on flames or direct contact, induction heating uses electromagnetic fields to generate heat within the metal itself. This contactless heating method offers unparalleled efficiency, safety, and precision.

The process involves generating an alternating magnetic field, which induces eddy currents in the conductive metal component. These currents heat the metal rapidly and uniformly, enabling quick preparation for alignment or welding. This technology is particularly favored in automotive repair, heavy machinery maintenance, and industrial fabrication where precision and speed are critical.

Metal alignment heating through induction offers distinct advantages over flame heating or resistance heating. It ensures localized heating without compromising the structural integrity of surrounding materials. Furthermore, induction heating enhances welding procedures by providing controlled preheating and post-heating, which reduces thermal stresses and defects.

Induction heating is not only a safer and cleaner alternative to open flames but also an eco-friendly solution that reduces CO₂ emissions and operational costs.

Overall, induction heating plays a vital role in improving welding quality and metal alignment by delivering precision heating that is fast, clean, and energy-efficient.

Importance of Heat Alignment

Proper metal alignment heating is crucial in ensuring the structural integrity and longevity of welded components. When metals are precisely aligned and uniformly heated, the welding process achieves better fusion, minimizing the risks of cracks, warping, or weak joints. Heat alignment helps relieve residual stresses that can cause distortion during or after welding.

In many industrial and repair applications, mechanical parts such as bolts, axles, and joints require alignment before welding can be executed effectively. Applying heat through induction allows the metal to expand gently and uniformly, facilitating exact positioning without the risk of overheating or damaging adjacent parts.

Furthermore, heat alignment contributes significantly to reducing downtime in repair operations. Faster and more accurate alignment means quicker preparation for welding tasks, which is essential in high-demand environments like automotive maintenance and heavy equipment servicing.

"Induction heating improves metal alignment by providing controlled, uniform heating that supports precision welding and reduces the risk of thermal damage."

Ultimately, investing in proper heat alignment methods translates into enhanced welding outcomes, increased component durability, and overall efficiency in production workflows.

Induction Heating Benefits

The benefits of induction heating in metalworking and welding are numerous, making it the preferred choice over conventional heating techniques. One of the key advantages is the contactless heating mechanism, which eliminates direct flame exposure and reduces fire hazards, making the workplace safer.

Induction heating is highly efficient due to its rapid heating capabilities. Metals can be heated within seconds to the desired temperature, significantly cutting down process times. This speed also leads to energy savings, as heat is generated only where needed without unnecessary loss.

Other benefits include:

-

Precision heating: Accurate control over temperature and heating area ensures consistent quality.

-

Environmental friendliness: No gas or open flames are involved, resulting in zero emissions during heating.

-

Reduced insurance costs: Safer processes lead to lower risks and insurance premiums.

-

Versatility: Compatible with a wide variety of metals and shapes.

-

Long equipment lifespan: Robust components designed for rough industrial environments.

These induction heating benefits collectively enhance productivity, safety, and sustainability in metal alignment and welding operations.

Welding Process Improvement

Integrating induction heating into the welding process results in significant improvements in both efficiency and quality. Preheating metals before welding minimizes thermal shock, reducing the likelihood of cracks and enhancing weld penetration. Induction heating allows for precise temperature control, ensuring metals reach optimal welding temperatures without overheating.

Additionally, induction heating facilitates post-weld heat treatment, which helps in relieving residual stresses and preventing distortion. This contributes to stronger, more durable welds that meet stringent quality standards.

The ability to heat specific areas rapidly and uniformly improves the overall welding workflow. Operators can prepare components faster, leading to reduced cycle times and increased throughput. Welding enhancement through induction heating also lowers the need for extensive rework and repairs, saving materials and labor costs.

"Induction heating integration transforms welding processes by delivering consistent heat, reducing defects, and accelerating production."

For industries where welding quality is paramount, such as automotive repair and heavy machinery maintenance, induction heating is a game-changing technology that elevates performance and reliability.

Precision and Control

One of the most compelling advantages of induction heating is its exceptional precision and control over the heating process. Unlike traditional methods, induction heating allows operators to target very specific areas without affecting surrounding materials. This localized heating capability is especially beneficial when working on complex assemblies or sensitive components.

Modern induction heaters come equipped with advanced controls that regulate power output, frequency, and heating duration, enabling tailored heating profiles for different metals and thicknesses. This level of control enhances the repeatability and consistency of heating cycles, which is critical for maintaining high welding standards.

Moreover, precision heating reduces the risk of overheating and thermal damage, preserving the mechanical properties of the metal. This is essential in applications requiring strict adherence to metallurgical specifications and safety regulations.

-

Adjustable power settings for various metal types

-

Programmable heating cycles for process consistency

-

Rapid response times for efficient operation

-

Non-contact heating eliminating contamination risks

Precision heating with induction technology empowers technicians to achieve superior metal alignment and welding quality, ensuring every project meets or exceeds expectations.

Quality Outcomes

The ultimate goal of using induction heating in metal alignment and welding is to achieve superior welding quality and component performance. The controlled heating environment reduces common welding defects such as porosity, incomplete fusion, and cracking.

By delivering uniform heat distribution, induction heating promotes consistent metallurgical properties across the weld joint. This uniformity enhances the strength, toughness, and fatigue resistance of welded parts, extending their service life.

Furthermore, induction heating contributes to cleaner welds by eliminating soot, scale, and other contaminants associated with flame heating. This results in a higher-quality finish that requires less post-weld cleaning and preparation.

"Welding quality is significantly enhanced through induction heating, providing stronger, more reliable joints and reducing costly failures."

Industries requiring high-precision welding, such as automotive repair and heavy equipment maintenance, benefit greatly from these quality outcomes. The use of induction heating not only improves product reliability but also boosts customer confidence and satisfaction.

Conclusion

In conclusion, induction heating is a transformative technology that profoundly enhances metal alignment and welding operations. Its contactless, efficient, and precise heating capabilities address many challenges faced in traditional heating methods, leading to safer, faster, and higher-quality outcomes.

Induction heating offers numerous advantages, from improving alignment accuracy to enhancing welding quality and minimizing operational risks. The induction heating benefits are undeniable. As industries increasingly seek greater efficiency and sustainability, induction heating emerges as a cutting-edge solution that aligns seamlessly with these objectives.

For professionals seeking to upgrade their metalworking processes, adopting induction heating technology offers a competitive edge by ensuring precise heating control, improved safety, and superior welding results.

"Embracing induction heating means investing in innovation that delivers consistent performance, environmental responsibility, and cost savings."

Explore the possibilities of induction heating to elevate your metal alignment and welding processes to new heights of excellence.